Machining of Hardox steels

Competence centre

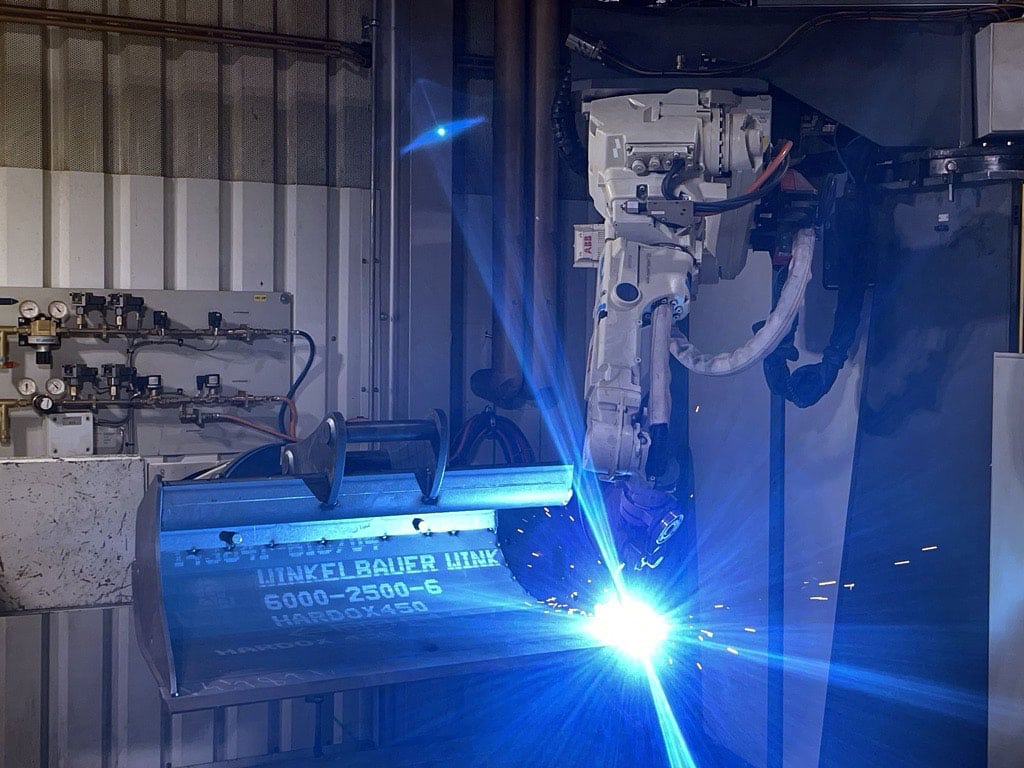

Winkelbauer has perfected how to weld highly wear-resistant and tough steels over the last few decades. Up to 6,000 tonnes of steel are processed annually in Winkelbauer's production facility in Anger near Weiz. However, it is not the mass, but rather the extreme hardness and toughness of the material that makes Winkelbauer one of the leaders in this field in Central Europe. Sheet metal thicknesses of up to 150 mm with a hardness of up to 600 Brinell are folded, milled, machined and welded together again. The result is high-quality products made from the highest Hardox grades and certified armoured steel. This discipline requires four important factors: Material. Machines. People. Market.

The material

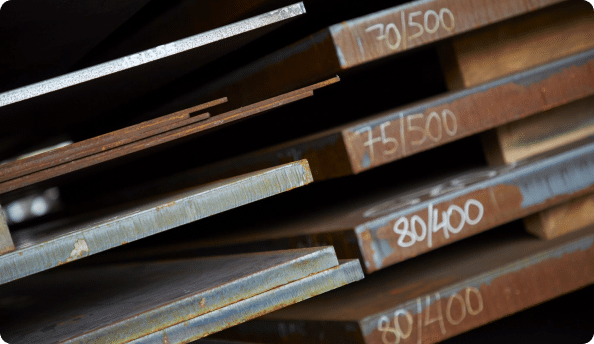

In the beginning there is the material </strong

Wear-resistant steel is defined as steel with a hardness of 350 to 600 HB. Modern wear-resistant steels must be fully hardened, have high toughness and yet be low-alloyed and therefore easy to weld. Winkelbauer has relied exclusively on Hardox steels from SSAB for decades. The use of material from the Swedish world market leader for wear-resistant steels is the basis for the highest product quality.

Requirements for the material:

- Wear resistance

- Toughness/elongation at break

- Processability

- Cost/benefit factor

- Constant quality

The machines

Modern infrastructure is not

necessary, but mandatory.

The best material on the market not only requires the best machines, it deserves them! Winkelbauer has a high-quality in-house process chain and state-of-the-art machinery with all the necessary technological steps – from cutting to the finished painted part. Hardox wear-resistant steels from 1 mm to 200 mm in various degrees of hardness of up to 600 Brinell are stored and processed.

Factors that make the difference:

- Process reliability in prefabrication

- Material availability

- Inhouse process chain

- Highest precision

- State-of-the-art machines

Four factors that make the difference.

Four factors that make the difference.

The human being

Learned the trade from

learnt from scratch.

For decades, long-standing and competent specialists have been working with high-strength and highly wear-resistant steels every day and therefore have the highest level of expertise in all production steps, especially in welding technology. This expertise is further expanded and perfected within the company through strategic apprentice training. The regular personal exchange of experience and knowledge with the professionals from SSAB, both in Sweden and at the Anger site in Styria, is also particularly important at Winkelbauer.

Choosing for us:

- Understanding for the end customer

- Qualification for wear-resistant steel

- Know-how in construction

- Continuous further training

- In-house training

The market

No welding without a market.

The markets for wear-resistant steels and other special steels are growing all the time. Energy efficiency and resource conservation are becoming increasingly important in all areas of life. As a result, the call for equally harder or high-strength and therefore lighter constructions is growing louder. Fossil-free steel in conjunction with CO² reduction is another challenging requirement of our generation.

Markets for wear-resistant steels:

- Demolition, recycling

- Agriculture and forestry, municipal

- Infrastructure construction & civil engineering

- Extraction, underground mining, quarrying

- Raw materials industry

- Protection